You can find check valves in wastewater household, industrial, and commercial applications. Their function is relatively the same — to provide a one-directional flow of fluids and gasses. However, these valves come in many different types, and choosing the correct check valve can be challenging.

Now, what is a check valve and where can you use them? What are the differences between a butterfly, a ball, and a swing check valve? Blackhawk Supply will gladly explain.

This in-depth guide will explain everything you need to know about check valves and help you pick the right one for your system.

Sounds interesting? Stick with us until the end.

What Is a Check Valve?

Let’s start with the basics. What does a check valve do in the piping system?

A check valve (also known as a non-return valve) is a mechanism used for one-directional control of fluids and gasses in the pipeline. This type of valve can prevent the water hammer — a shockwave or pressure surge that can damage the piping system.

In other words, the check valve’s purpose is to prevent backflow and protect mechanical equipment in the piping.

Advantages

- Prevents water hammer (fluid pressure surge)

- Protects the piping system and its components

- Many categories and types of check valves available on the market

- Extremely durable and maintenance-free

Disadvantages

- Hard to assess the condition of the valve’s internal parts

- Difficult to understand the valve position (open or closed)

- Limited installation configurations

How Does a Check Valve Function in a Pipeline?

Now, what is the purpose of a check valve?

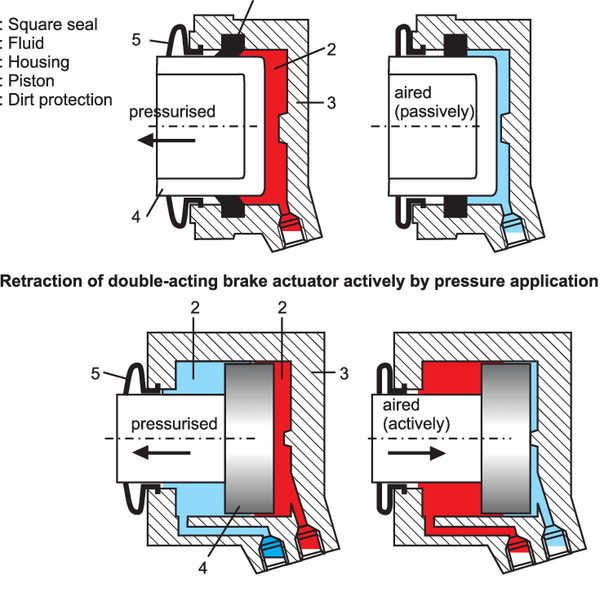

In short, it allows the liquids and gases to flow in one direction while blocking the backward flow. These devices usually have a spring mechanism that automatically closes the valve using the pressure of the medium flow.

Here’s how the check valve works:

- The liquid comes in contact with the check valve.

- High liquid pressure (also known as upstream or cracking pressure) increases and compresses the spring-loaded inline mechanism inside the valve.

- The spring pushes the disc (gate, ball, or diaphragm), opening the valve and allowing the fluid (or gas) to flow.

- When the pressure decreases, the spring seals the valve and stops the flow.

Proper installation is required to ensure that the flow goes in the right direction. Otherwise, the fluid or gas won’t move through the system and could even cause damage. You can identify the flow direction by the arrow markings on the valve’s housing.

What Does a Check Valve Do?

As you know, check valves are used to prevent reverse flow in piping systems. Let’s talk about how you can use it for your systems.

- Flow control in heating, ventilation, and air conditioning (HVAC) systems.

- To prevent unnecessary shutdowns of the piping system when backflow could cause a shockwave that would damage the internal equipment.

- To ensure the system contains only clean drinking water and prevent the wastewater from re-entering the system.

- Hydraulic check valves control block opposite direction flow of oil in hydraulic devices.

- To prevent liquid drainage and siphoning.

- To avoid mixing of the fluids and gasses into one stream.

- To prevent reverse flow that happens when the air pressure in secondary systems rises above the pressure in the primary system.

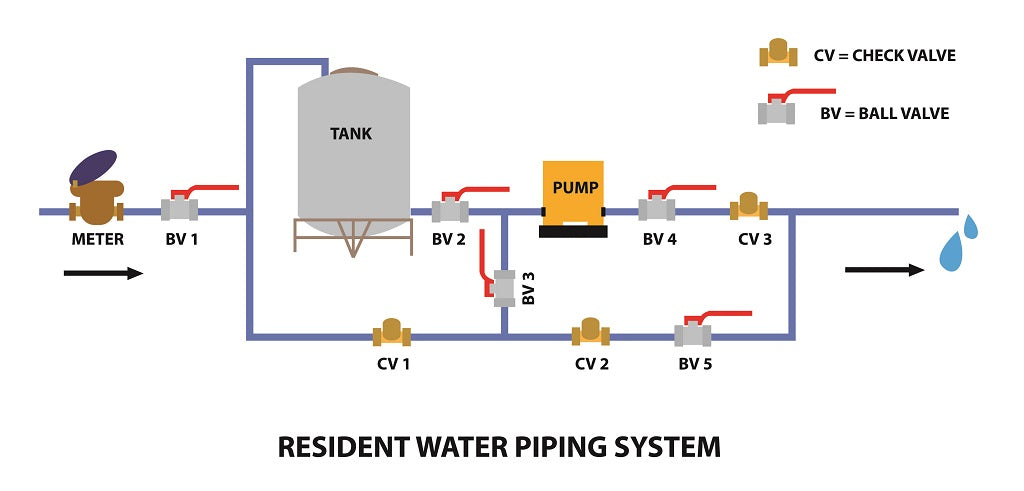

Check valves are used in most houses, offices, and industrial environments. Now, let’s see the two most popular categories of applications.

Water Applications

Check valves can be found in water applications, such as washing machines, filters, and aquariums. Some of the functions they perform include:

- Contamination prevention. Check valves isolate the outlet side of the valve from outside sources, such as the wastewater. Consequently, they prevent contamination and ensure that the drinking water stays clear.

- Protection against overflow. These valves block fluids from re-entering the system, eliminating the chance of an overflow and pressure surge.

- Internal pressure stabilization. Water pumping applications can stay clear from debris, keeping the internal pressure at optimal levels.

- Water discharge. Duckbill check valves prevent the discharged water from coming back into pumps when it’s turned off.

Pneumatic (Air) Applications

Pneumatic (air compressor) check valves are used for one-directional airflow. In other words, they allow the compressed air to flow into the system and prevent it from flowing back. These valves rely on pressure differential to open or close the valve.

Aircheck valves are typically used for pressure control. They allow certain parts of the compressor to be depressurized to protect internal equipment. You can find them in gas mixing systems, aerospace applications, home heating systems, aircraft hydraulic systems, and other environments.

Check Valve Types

Check valves have the same purpose, but they are available in many different types designed for specific applications. It’s important to understand the classification of check valves before you can choose the right one for your system.

Here are the most popular categories and types of these valves.

Swing Check Valve

Jomar 105-408G S-511G, 2" Y-pattern Swing Check Valve

Swing check valves control the flow using a disc mechanism. The disc inside the valve opens and closes based on the pressure level. This type of valve is often used in firefighting and sewage systems.

Swing check valves can have a top-hinged or tilting disc mechanism.

Top-Hinged

The top-hinged swing check valve has the disc at the inner top of the device. The hinge opens the disc when the pressure increases and shuts it down as the pressure drops.

Tilting-Disc

The tilting-disc valve has a spring-loaded dome-shaped disc that opens and closes the valve almost instantaneously.

Lift Check Valves

Lift check valves have a ball or a piston that gets lifted from the pressure, allowing the valve to open and close. The applications for these valves include make-up water, N2 systems, dump lines, and feed water control in the industrial sector.

Piston

The piston in the check valve allows the fluid to flow as long as the gravitational closure keeps the pressure steady. These valves sometimes have a spring to improve the flow control.

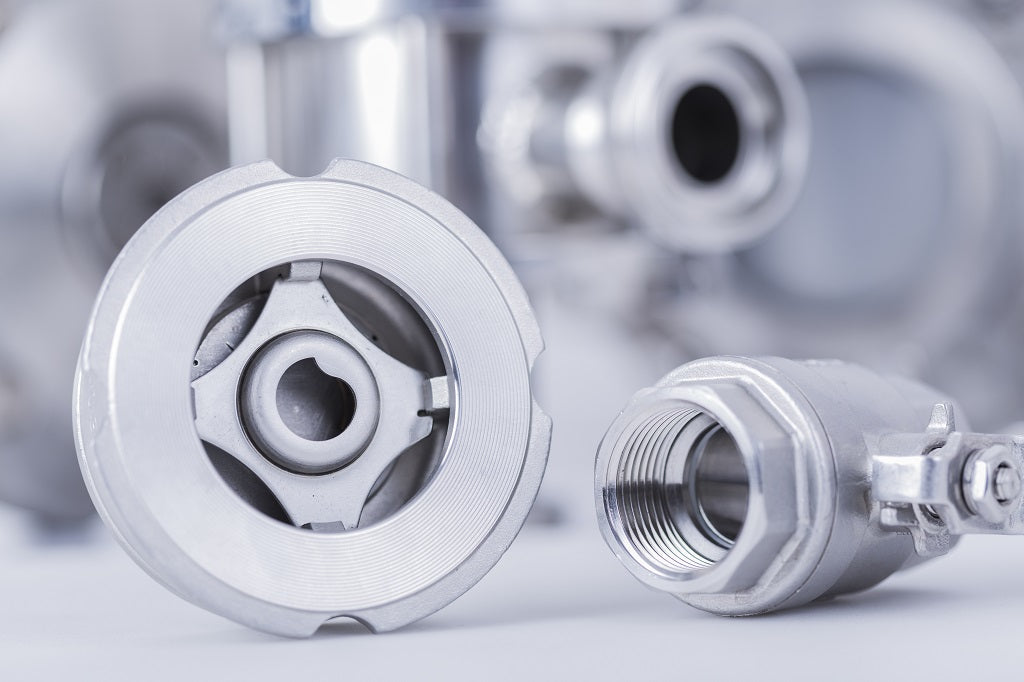

Ball

A spring-loaded or flee-floating ball allows one-directional flow in the valve. Ball check valves have a tight seal to stop the reverse flow, making them useful for high-pressure and high-velocity applications.

Butterfly Check Valves

Stop Check Valves

Stop check valves are found in many boilers, steam generators, power plants, and safety systems.

Foot Check Valves

Hayward FV10400SA 4" PVC Foot Valve Screen

Foot check valves are used for fuel tanks, water wells, and other systems with the suction lines below the pump. They can keep the debris and liquid from getting into the system to prevent clogging, energy-wasting, and potential damage to water pumps.

Materials

Depending on the application, the components of check valves can be made from PVC (polyvinyl chloride), PP (polypropylene), stainless steel, brass, and other materials.

Brass

A brass check valve is usually found in low-pressure applications. It has great durability and works excellent for water, oil, and fuels. However, brass is less resistant to corrosion, heath, seawater.

PVC

Polyvinyl chloride material is often used in check valves in water management and irrigation systems because of its resistance to acids, chloride solutions, seawater, and other corrosive fluids. PVC shouldn’t be used for chlorinated hydrocarbons and other fluids with high temperatures (over 60 degrees Celsius).

Polypropylene

Polypropylene material has strong corrosion resistance, making them great for inorganic acids, aqueous solutions, and other media that can corrode metals. You can use them for aggressive fluids, water, and liquid food applications.

Stainless Steel

Stainless steel and titan check valves have excellent resistance to low and high temperatures, as well as corrosion. On the downside, this material is more expensive than other solutions.

How to Choose the Right Check Valve

Choosing the check valve is much easier when you know about different types of mechanisms and their applications. However, you need to consider other criteria to pick the right valve at a reasonable price:

- Risk of the water hammer in your systems.

- The highest and lowest temperature of the media.

- Maximal pressure in the system.

- Acceptable pressure loss.

- Envelope dimensions and line sizes.

- Type of fluids and material compatibility.

- Mounting orientation (vertical or horizontal).

- Accessibility of the applications (for maintenance and repairs).

Another option is to ask a professional company for help. They can assess your systems to find the safest and most cost-effective solutions for flow control.

Conclusion

The check valve is the best solution for one-directional flow control. These valves prevent backflow, eliminating potential damage from overflowing, pressure surges, and water hammers.

Choosing a check valve shouldn’t be much of a problem now that you know about their categories. However, you can always ask experts for help.

Blackhawk Supply has a wide selection of check valves including air compressors, butterflies, and ball valves. Check it out!